Air Bending | Hand Bending

Aristo-Tec offers air bending and hand bending for small quantity orders. These methods are both very labor intensive, but for small runs will most likely be the quickest and most economical solution.

Aristo-Tec offers air bending and hand bending for small quantity orders. These methods are both very labor intensive, but for small runs will most likely be the quickest and most economical solution.

To best explain air bending and hand bending it is important to define the bending process in relationship to custom wire forming. Bending is a process where the wire is deformed by physically changing its shape beyond the yield strength but not beyond the tensile strength. This means the material is physically bent by force great enough to form the determined angle or bend without allowing the wire to rebound back to its original shape or break.

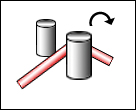

Air and hand bending are accomplished by placing a section of straight and cut wire between a stationary pin and a second roller pin. The roller pin is propelled (by air or hand) around the circumference of the stationary pin, bending the wire around the stationary pin. The diameter of the stationary pin determines the radius of the bend.

Air and hand bending are accomplished by placing a section of straight and cut wire between a stationary pin and a second roller pin. The roller pin is propelled (by air or hand) around the circumference of the stationary pin, bending the wire around the stationary pin. The diameter of the stationary pin determines the radius of the bend.

Air and hand bending are used for small or short production runs. Due to the amount of physical labor involved, it is not economical or practical for large runs.

If you would like more information about Aristo-Tec’s air or hand bending process or if it is the right solution for your project please contact at 724-626-5900 or use the online communication buttons below.